Product

Sintered Products Portfolio

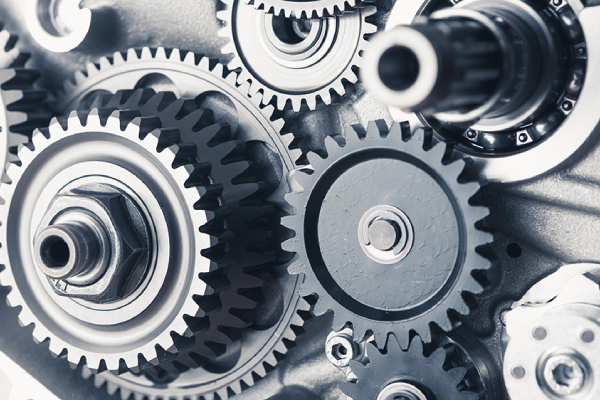

Automotive Components

- Helical Gears

- Pinion Gears

- Sprockets

- Inner/ Outer Rotors

Mechanical Components

- Gears

- Pulleys

- Cams

- Output carriers

Sintered Bearings

- Oil Impregnated Bearings

- Self Lubricating Bearing Sleeve

- Flanged Bearings

Secondary Processes

- Steam Treatment

- Heat Treatment

- Surface Coating

- Sizing

- Assembly

- Oil Impregnation

- Machining

- Gear Rolling

Automotive Components

Helical Gears

Pinion Gears

Sprockets

Inner/ Outer Rotors

Mechanical Components

Gears

Pulleys

Cams

Output Carriers

Sintered Bearings

Oil Impregnated Bearings

Self Lubricating Bearing Sleeve

Flanged Bearings

Secondary Processes

Steam Treatment

Heat Treatment

Surface Coating

Sizing

Assembly

Oil Impregnation

Machining

Gear Rolling

What are the benefits of using Sintering?

- Able to produce complex shapes

- Self Lubrication Properties

- Recognised as a Green Technology

Sinstering Process

Sintering is an efficient metal forming technology to manufacture high precision components. This process can avoid, or greatly reduce, the need to use metal removal processes, thereby drastically reducing yield losses in manufacture and often resulting in lower costs.

Mixing

Compacting

The mixed powder is placed in a high precision tooling, then compacted by a vertical press machine to form a compressed part called Green compact.

Sintering

The Green compact is placed into a sintering furnace, where it is heated in gas atmosphere at temperatures below the melting point of base metals. An alloy component of near net shape is then ready for delivery or further processing.